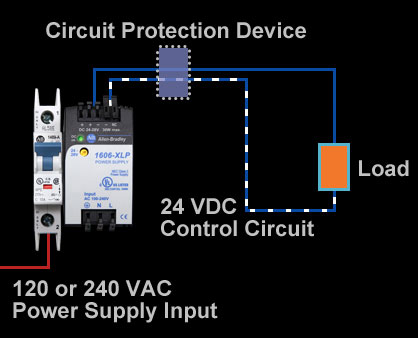

When switched mode power supplies are used to energize control circuits in an industrial application, some form of circuit protection is typically applied between the power supply and the control-circuit loads to protect the equipment on the control circuit, should a fault occur.

When switched mode power supplies are used to energize control circuits in an industrial application, some form of circuit protection is typically applied between the power supply and the control-circuit loads to protect the equipment on the control circuit, should a fault occur.

Power supplies have built-in protection, but this protection is designed to protect the power supply itself. Control circuit faults can occur in such a way as to damage sensitive electronic components on the circuit long before the power supply shuts down-if it ever does.

Traditional Circuit Protection (Fuses and Thermo-magnetic circuit breakers) have often been applied to protect the control circuits. This technology is typically quite effective if a short occurs while the circuit is energized.

But, not all faults follow this pattern.

On an installation or repair, a wiring problem can create a short circuit that will only be discovered once the circuit is powered up.

Sometimes the load on a circuit increases beyond its design due to mechanical equipment failure. For example a bearing failure causes a motor to overload, drawing additional current.

And sometimes, there is the opposite problem: normal current-inrush when energizing inductive or capacitive loads can cause nuisance tripping, when no actual fault occurred.

+ Click to read more on Electronic Circuit Protection

The nature of traditional Circuit Protection (Fuses and Thermo-magnetic circuit breakers) is that they "assume" infinite current available on a circuit. In the real-world on non-infinite budgets, however, power supplies are a specified based on the expected demands of the circuit they will be energizing. In fault or overload conditions, the current observed on the circuit can go up, while the voltage falls. This condition of high current and low-voltage can remain long enough-before the thermal protection [bimetal] of traditional circuit breakers kicks in-to damage components on the circuit.

With 1694 Electronic Circuit Protection the disconnection of the load happens electronically by a transistor. The trip characteristics of a 1694 Electronic Circuit Protector tolerates a momentary inrush current from e.g. switching on a capacitive load and limits the maximum current. In case of a current being too high for too long the 1694 Electronic Circuit Protector disconnects typically in 3 seconds if the current reaches 1.05 times the nominal current rating In. Please refer to typical trip characteristics curve

1694 Electronic Circuit Protection trips faster and safer than a fuse or a thermal-magnetic circuit breaker allows for reliable protection of sensitive equipment, such as PLCs, controls or sensors, when they are connected directly to the same power supply as the Bulletin 1694 protection module.

Fuses are available with various tripping characteristics. Thermo-magnetic circuit breakers, too, are available with various trip characteristics, often expressed in graphical form as "trip curves." The typical "C curve" breaker has a magnetic trip activated at 5 ... 10 times the rated current of the circuit breaker and is intended to accommodate inrush current from inductive loads. "B curve" breakers have a magnetic component at lower thresholds and are typically used on resistive loads. "Z curve" breakers (available from other manufacturers) are often stated to protect solid state circuits, and have an even lower tripping threshold. Note, all have similar thermal characteristics.