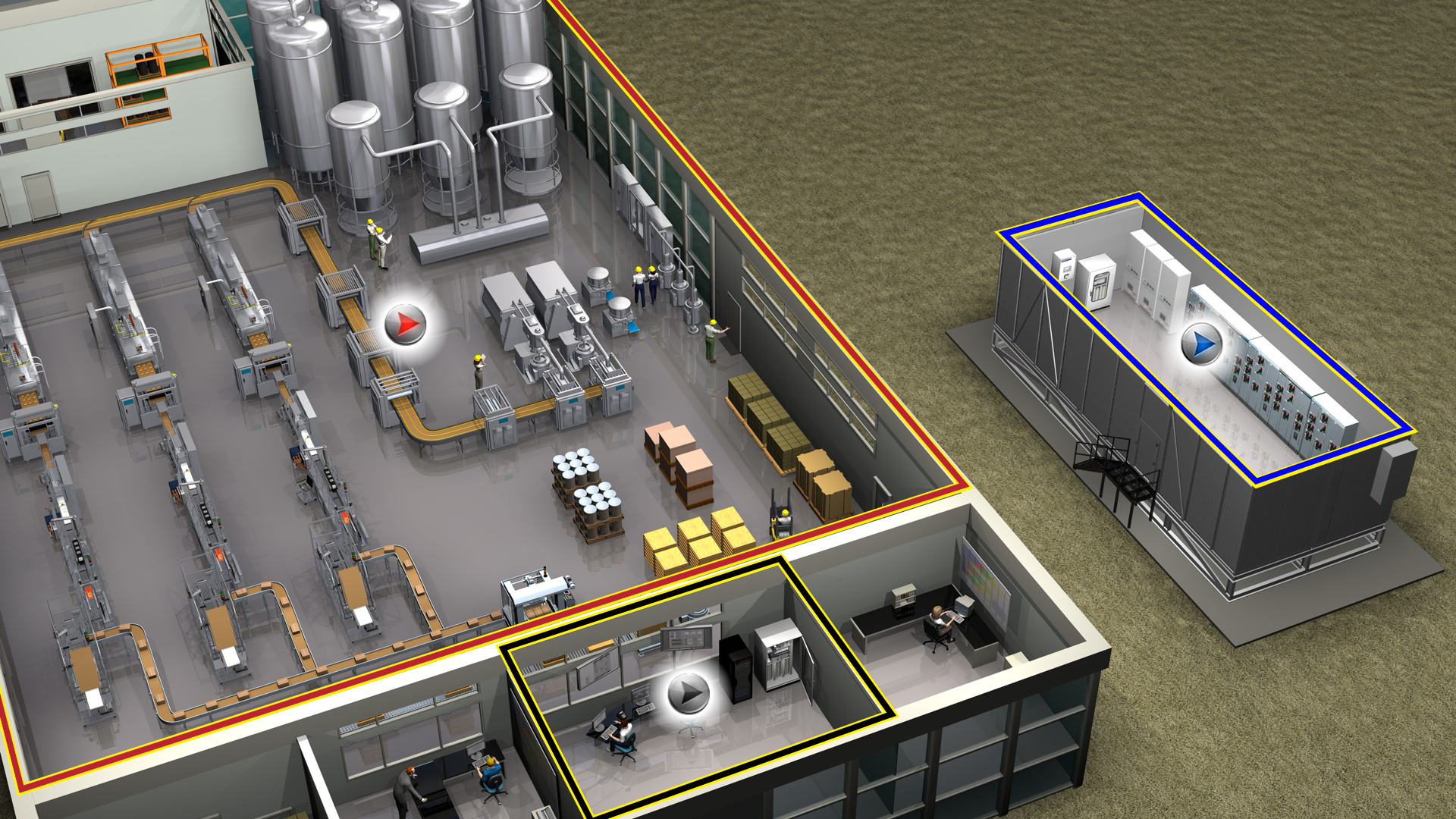

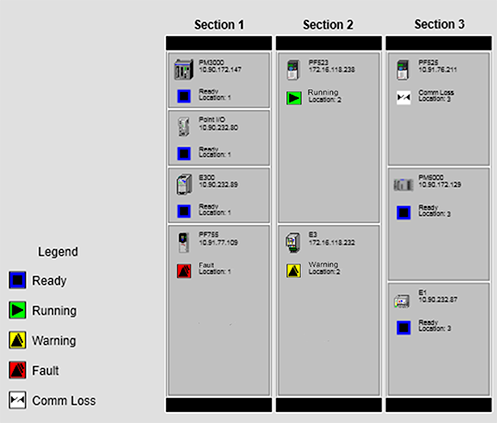

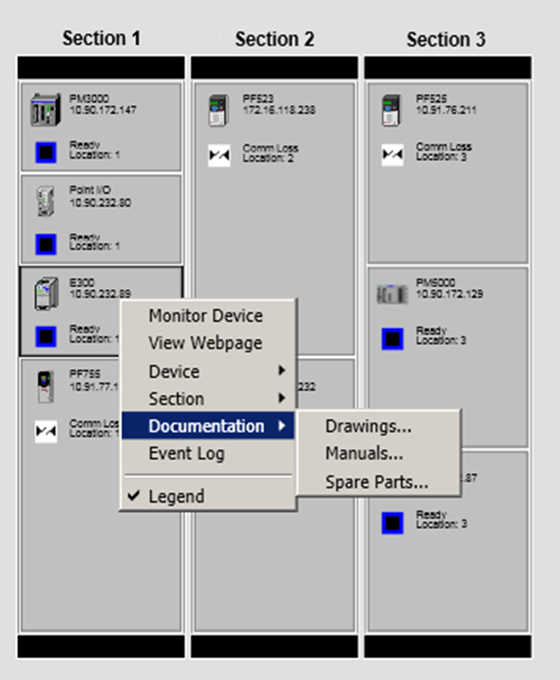

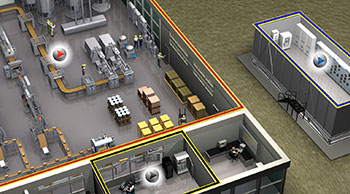

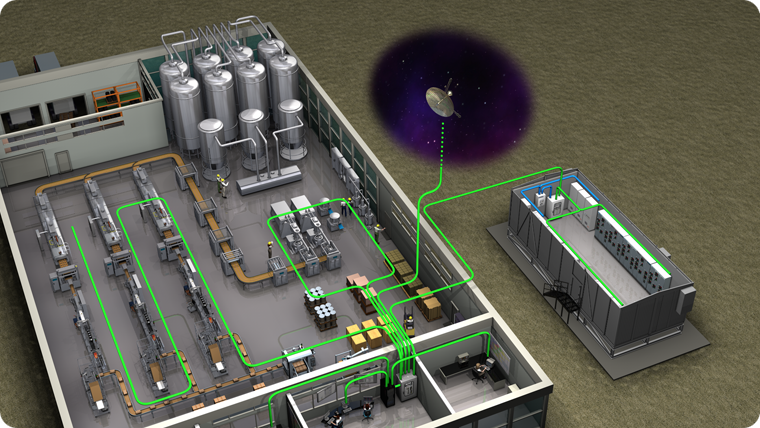

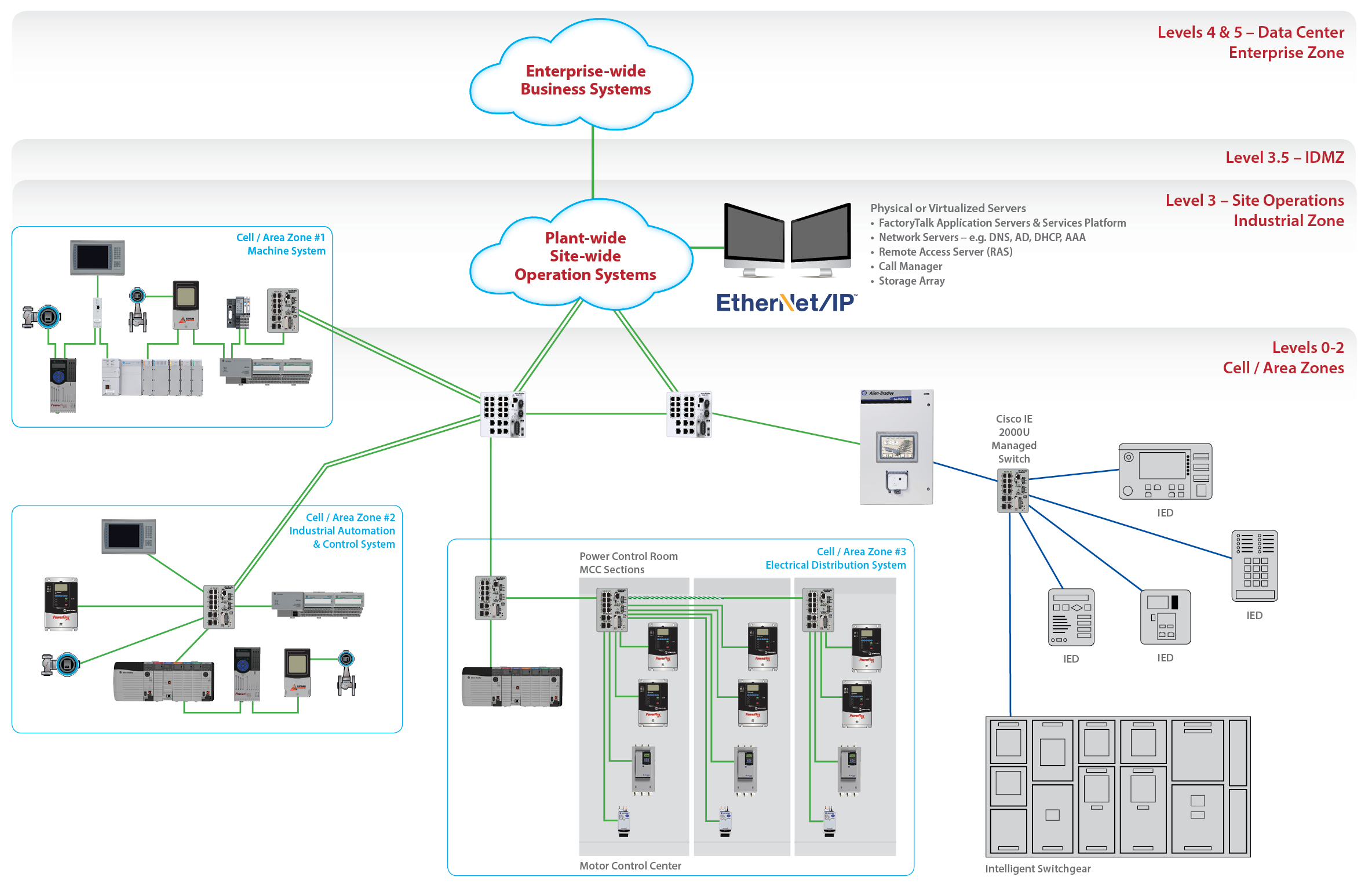

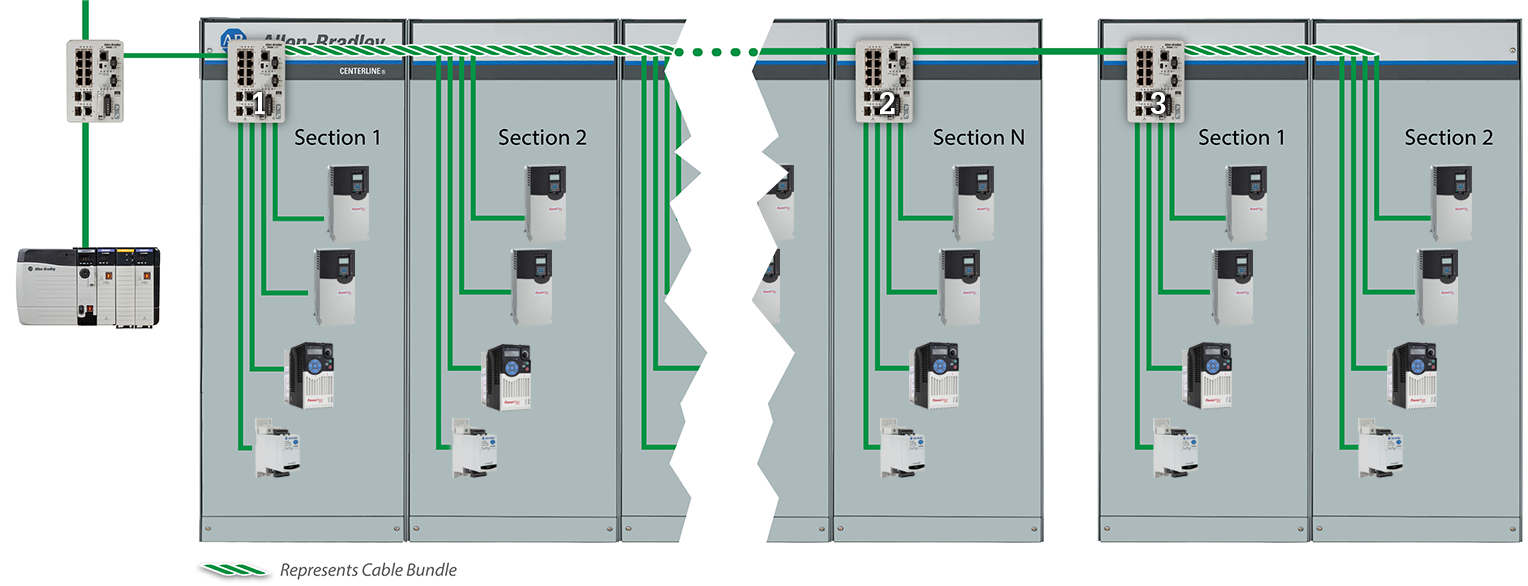

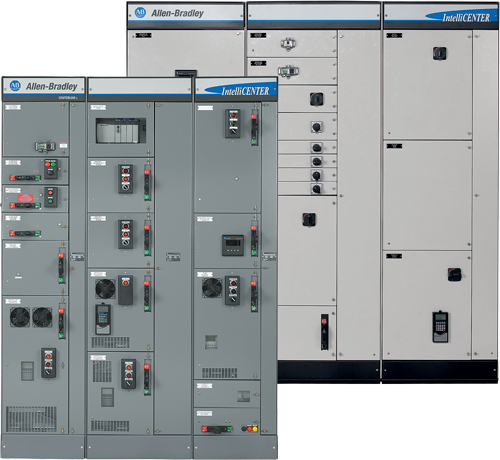

IntelliCENTER software offers a virtual representation of your MCC lineup.

- Factory configured software specific to your MCC

- A more simplified user experience

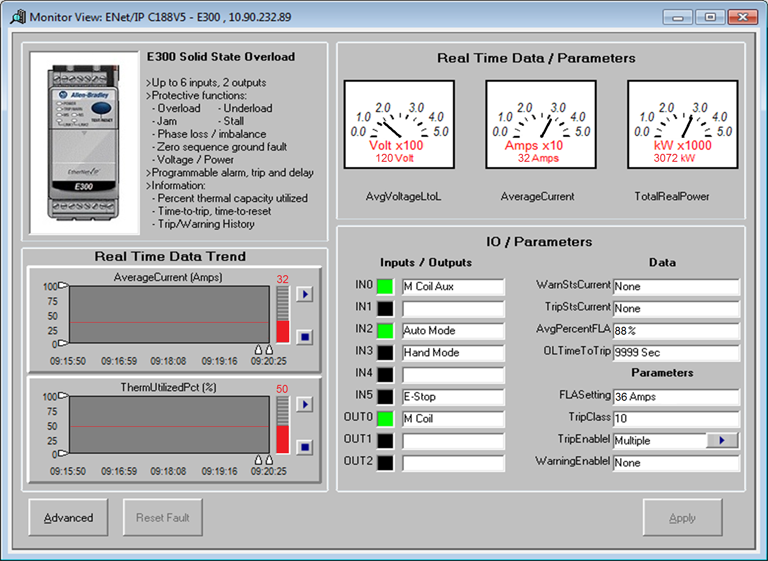

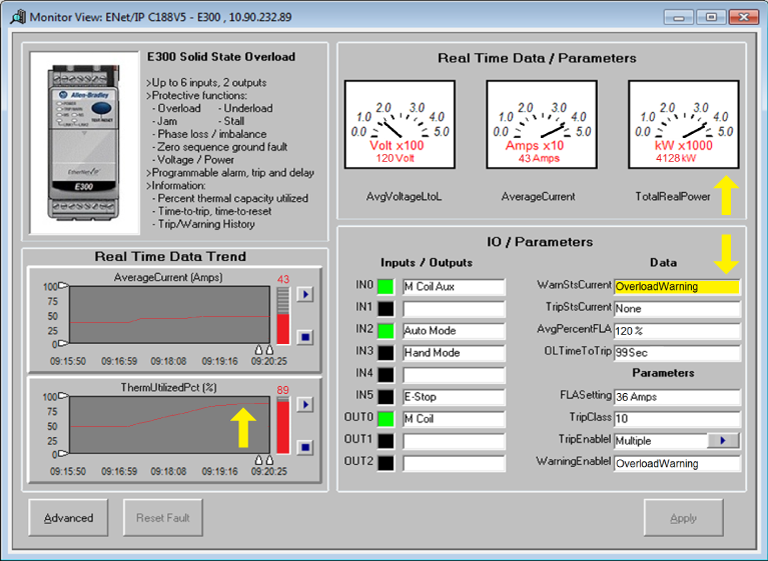

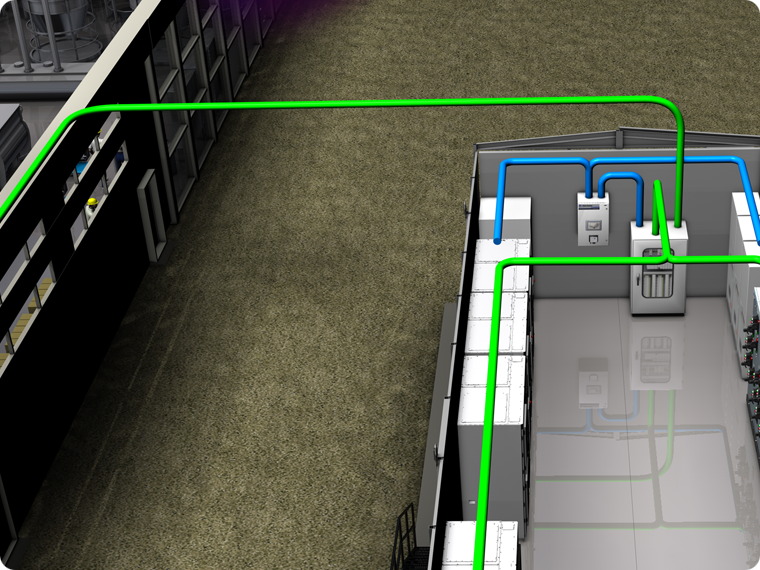

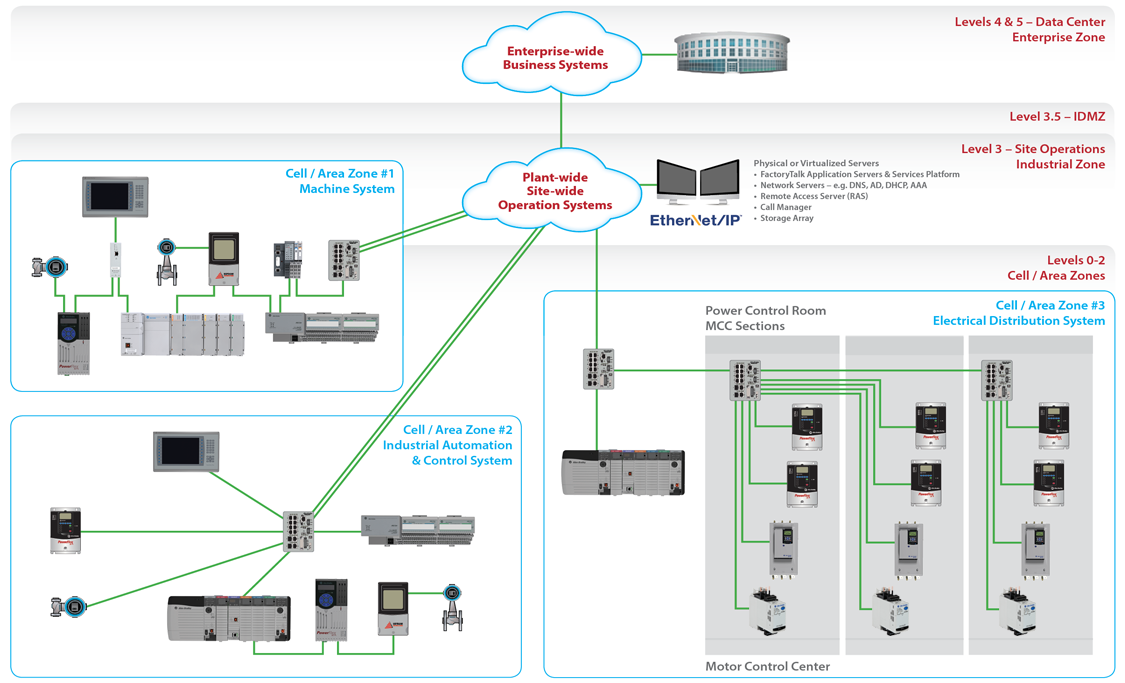

- Monitor, diagnose and modify your MCC from anywhere

- Real-time energy consumption analysis

- Use data-trending information for predictive maintenance

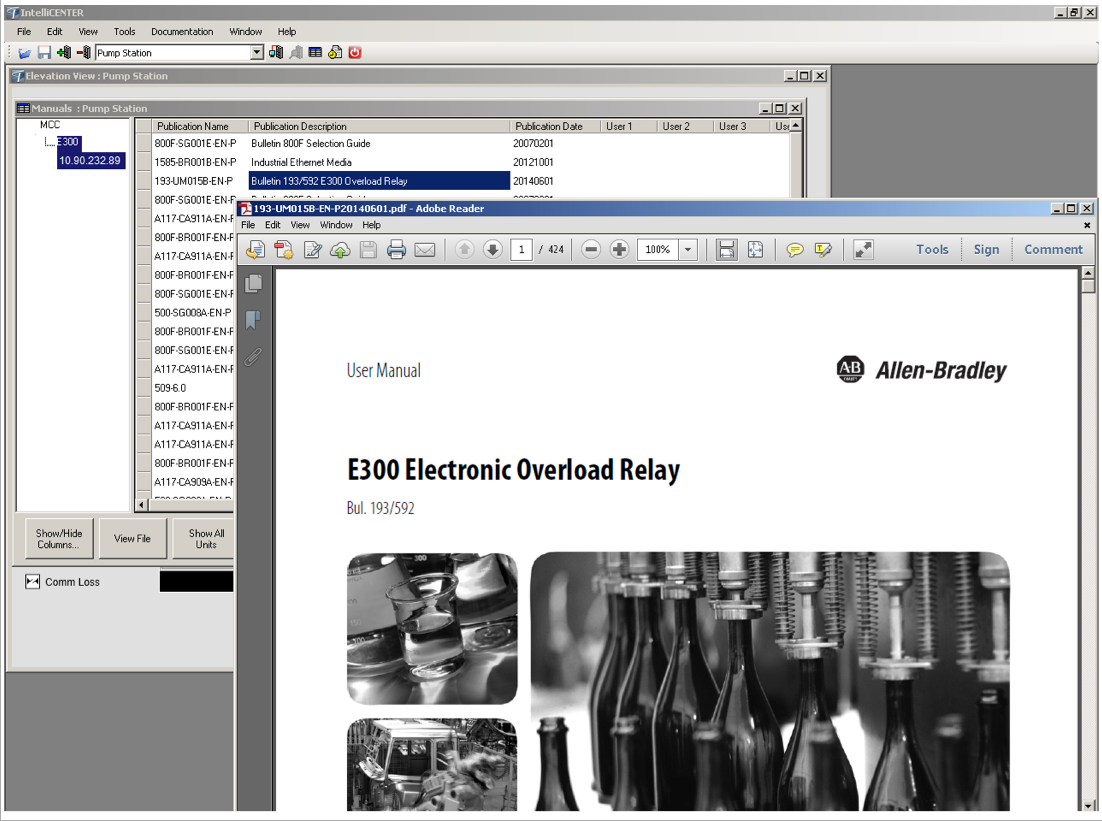

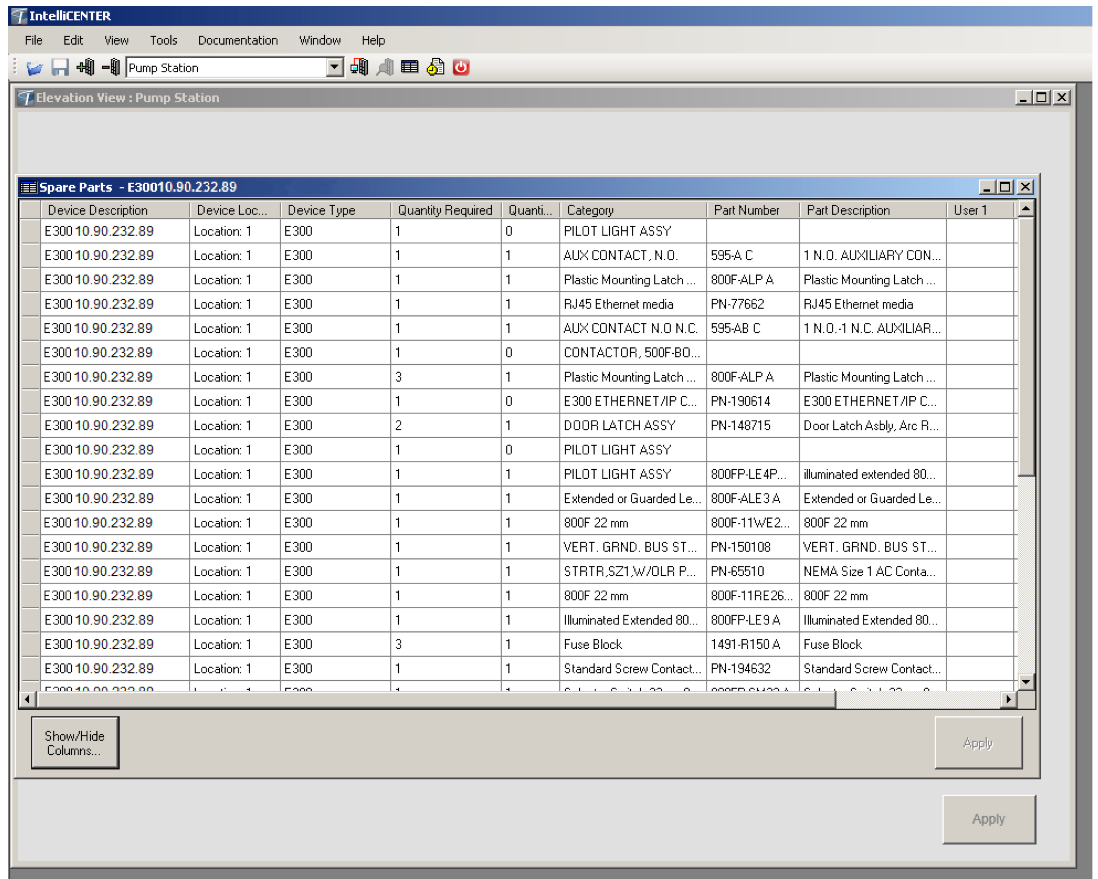

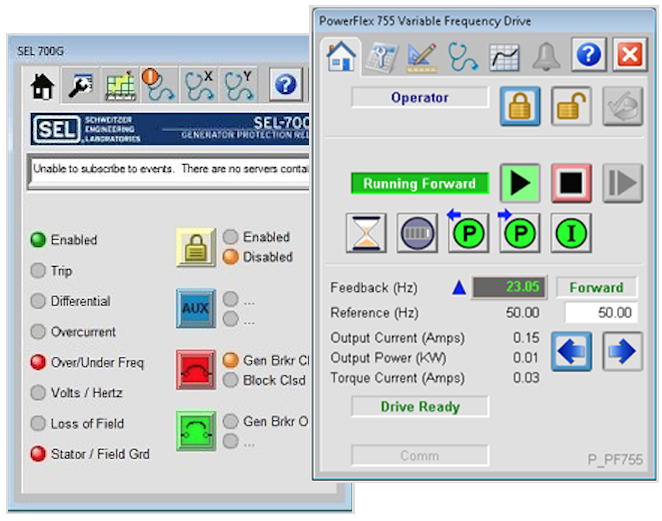

- Access electronic documentation

- Integrate IntelliCENTER software features into your separate HMI with included ActiveX controls